www.mineralienatlas.de

www.mineralienatlas.de Introduction: Building Your Own Tuff Shed KR-600 (DIY Guide) This guide provides a step-by-step approach to constructing a Tuff Shed KR-600 from the kit. This is a substantial project that requires careful planning, attention to detail, and potentially assistance from a friend or family member. Make sure you have the appropriate tools and safety equipment before starting. Remember to always follow the manufacturer's instructions included in your kit, as this guide is intended as a helpful supplement and not a replacement for the official documentation.

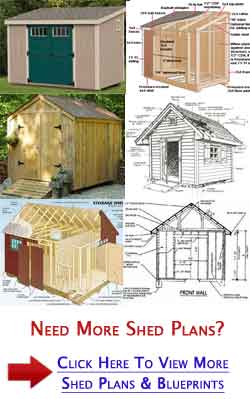

Step 1: Site Preparation and Foundation Before you even open the box, a solid foundation is paramount. Choose the Location: Consider sunlight, drainage, proximity to utilities, and local building codes. Prepare the Site: Clear the area of all vegetation, rocks, and debris. Ensure the ground is level. Foundation Options: You have several options including a concrete slab, gravel pad, or pre-made shed foundation. The gravel pad is often the most economical and practical choice for the KR-600. Create a gravel bed approximately 4-6 inches deep and larger than the shed's footprint. Compact the gravel thoroughly. Check for Level: Use a level to ensure the foundation is perfectly level in all directions. Adjust as needed.

Step 2: Inventory and Organization This is a crucial step to prevent headaches later. Unpack and Inventory: Carefully unpack all components of the Tuff Shed kit. Use the provided parts list to inventory all pieces. Organize: Group similar components together (e.g., wall panels, roof trusses, hardware). This will speed up the assembly process. Check for Damage: Inspect all components for any damage incurred during shipping. Contact Tuff Shed if you find any damaged or missing parts.

Step 3: Wall Assembly This is where the shed begins to take shape. Base Plates: Begin by assembling the base plates (bottom framing) of the walls. Refer to the plans for the correct placement of each piece. Use the provided screws or nails to secure the pieces together. Wall Panel Attachment: Position the pre-fabricated wall panels onto the base plates. Ensure they are properly aligned and square. Attach the panels to the base plates using screws or nails. Wall Raising: With assistance, carefully raise each wall panel into the upright position. Temporarily brace the walls to keep them from falling over. Wall Connection: Connect the wall panels to each other at the corners using screws or nails. Ensure the walls are plumb (vertically straight) and square.

Step 4: Roof Truss Installation The roof is a critical component. Truss Placement: Lift the roof trusses into position, spacing them according to the instructions. Truss Attachment: Securely attach the trusses to the top of the wall panels using screws or nails. Use hurricane ties or other appropriate connectors for added strength, especially if you live in an area prone to high winds. Sheathing Installation: Attach the roof sheathing (plywood or OSB) to the trusses, starting at the bottom edge and working your way up. Stagger the seams between sheets for added strength. Secure the sheathing with nails or screws.

Step 5: Roofing Installation Protecting your shed from the elements. Underlayment: Install roofing underlayment (felt paper or synthetic underlayment) over the roof sheathing. Overlap the seams according to the manufacturer's instructions. Shingle Installation: Install the shingles, starting at the bottom edge of the roof and working your way up. Overlap the shingles according to the manufacturer's instructions. Use roofing nails to secure the shingles. Ridge Cap: Install the ridge cap along the peak of the roof to seal the joint.

Step 6: Door and Window Installation Adding access and light. Door Framing: Install the door frame according to the instructions. Ensure the frame is plumb and square. Door Installation: Hang the door in the frame, ensuring it swings freely and closes properly. Install the door hardware (knob, latch, hinges). Window Framing: Install the window frame according to the instructions. Ensure the frame is plumb and square. Window Installation: Install the window in the frame. Seal the edges of the window with caulk to prevent leaks.

Step 7: Siding Installation (If Applicable) Adding protection and aesthetics. Siding Preparation: Prepare the siding according to the manufacturer's instructions. This may involve cutting the siding to size and applying a primer. Siding Installation: Install the siding, starting at the bottom of the walls and working your way up. Overlap the siding according to the manufacturer's instructions. Secure the siding with nails or screws. Trim Installation: Install the trim around the doors, windows, and corners of the shed. This will help to seal the joints and give the shed a finished look.

Step 8: Final Touches and Inspection Ensuring a complete and safe build. Caulking: Caulk all seams and joints to prevent water leaks. Pay particular attention to the areas around the doors, windows, and roof. Clean Up: Clean up any debris and trash from the construction site. Inspection: Carefully inspect the shed to ensure that everything is properly installed and secured. Make any necessary adjustments or repairs. Touch-Up Paint: Apply touch-up paint to any areas that are scratched or damaged.

Conclusion: Enjoy Your New Tuff Shed Congratulations! You have successfully built your own Tuff Shed KR-600. This new space can now be used for storage, a workshop, or any other purpose you desire. Remember to periodically inspect your shed for any signs of damage or wear and tear and perform any necessary maintenance to keep it in good condition for years to come.

Mineralatlas Lexikon

www.mineralienatlas.de

www.mineralienatlas.de Mineralatlas Lexikon

www.mineralienatlas.de

www.mineralienatlas.de Volcanic Tuff (near Cripple Creek, Colorado, Usa) 1

www.flickriver.com

www.flickriver.com

0 komentar:

Posting Komentar