www.pinotspalette.com

www.pinotspalette.com Opening: Embrace the Green Thumb with a DIY Garden Shed Want to expand your gardening hobby, keep your tools organized, and add a charming feature to your backyard? Building a garden shed with integrated raised beds is a fantastic project that combines storage and growing space. This guide will walk you through creating your own functional and beautiful garden shed.

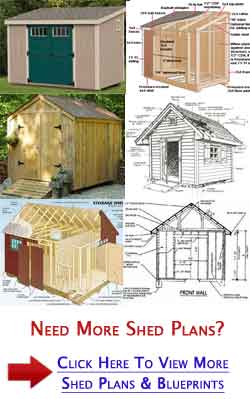

Step 1: Planning and Design Before you grab your hammer, a solid plan is essential. Consider these factors: Shed Size: How much storage space do you need? Factor in tools, potting supplies, and maybe even a small workbench. Raised Bed Dimensions: How many raised beds do you want, and what size will they be? Think about the plants you plan to grow. Location: Where will the shed be located in your yard? Consider sunlight, drainage, and proximity to water sources. Materials: Choose durable, weather-resistant materials like treated lumber, cedar, or composite decking. Design Software or Sketches: Create detailed plans or sketches. This will help you visualize the finished product and estimate material costs.

Step 2: Gathering Materials and Tools Based on your design, make a comprehensive list of materials. You'll likely need: Treated lumber for framing (walls, roof, floor, raised beds) Exterior siding (wood, metal, or composite) Roofing materials (shingles, metal roofing) Fasteners (screws, nails, bolts) Hardware (hinges, latches, handles) Landscaping fabric (for raised beds) Soil and compost (for raised beds) Tools: Saw (circular saw, miter saw) Drill/driver Level Measuring tape Square Hammer Safety glasses Gloves

Step 3: Building the Shed Foundation and Floor A solid foundation is crucial for a stable shed. Prepare the Site: Level the ground where the shed will be located. You may need to remove topsoil and add gravel for drainage. Frame the Foundation: Build a rectangular frame using treated lumber. Ensure it's square and level. Add Floor Joists: Space the joists evenly within the frame to support the floor. Install Flooring: Attach treated plywood or decking to the joists, creating a solid floor.

Step 4: Framing the Walls Construct the walls one at a time, then raise and secure them. Cut Wall Studs: Cut the studs to the correct length, based on your desired wall height. Assemble Wall Frames: Attach the studs to top and bottom plates, ensuring they are evenly spaced. Frame Openings: Create openings for doors and windows, adding headers for support. Raise and Secure Walls: Carefully raise each wall frame and secure it to the floor frame. Use temporary braces to hold the walls upright. Connect Walls: Connect the walls to each other at the corners, ensuring they are plumb and square.

Step 5: Building the Roof The roof provides shelter and protects the shed from the elements. Frame the Rafters: Cut the rafters to the correct length and angle, based on your desired roof pitch. Attach Rafters: Attach the rafters to the top plates of the walls, creating a stable roof frame. Install Sheathing: Cover the rafters with plywood or OSB sheathing. Apply Roofing Material: Install your chosen roofing material according to the manufacturer's instructions.

Step 6: Installing Siding and Trim Siding protects the walls and adds to the shed's appearance. Attach Siding: Install the siding material, overlapping each course according to the manufacturer's instructions. Add Trim: Install trim around doors, windows, and corners to create a finished look.

Step 7: Building the Raised Beds Integrate the raised beds into the shed's design. Frame the Beds: Build rectangular frames using treated lumber, matching the dimensions in your plan. Attach to Shed: If designed to be attached, secure the beds to the shed walls or create a free-standing structure. Line the Beds: Line the inside of the frames with landscaping fabric to prevent soil from escaping. Fill with Soil: Fill the raised beds with a mixture of topsoil, compost, and other amendments.

Step 8: Adding Doors, Windows, and Finishing Touches Complete the shed with functional and decorative elements. Install Doors and Windows: Install doors and windows, ensuring they are plumb and square. Add Hardware: Install hinges, latches, and handles. Paint or Stain: Paint or stain the shed to protect the wood and enhance its appearance. Landscaping: Add plants and landscaping around the shed to create a cohesive look.

Conclusion: Enjoy Your New Garden Oasis Congratulations! You've successfully built a garden shed with raised beds. Enjoy the extra storage space, the convenience of having your tools close at hand, and the satisfaction of growing your own plants. Your DIY garden shed is a valuable addition to your property, providing years of enjoyment and productivity.

Ideas For Woodworking Projects

readwiring.blogspot.com

readwiring.blogspot.com Diy Craft Projects

:max_bytes(150000):strip_icc()/DIY-Watermelon-Banner-BugabooCity-5b5fc52bc9e77c002c271218.jpg) www.thesprucecrafts.com

www.thesprucecrafts.com Creative Diy Projects: Craft Ideas To Brighten Your Home

www.pinotspalette.com

www.pinotspalette.com

www.freeimages.com

www.freeimages.com  www.flickriver.com

www.flickriver.com  geology.com

geology.com  www.stormystuff.com ```html

www.stormystuff.com ```html  exylgtqyu.blob.core.windows.net

exylgtqyu.blob.core.windows.net  www.homedepot.com

www.homedepot.com  www.milwoodgroup.com

www.milwoodgroup.com  theverandaman.co.uk

theverandaman.co.uk  www.dreamstime.com

www.dreamstime.com  en.wikipedia.org

en.wikipedia.org  www.mineralienatlas.de

www.mineralienatlas.de  www.familyhandyman.com

www.familyhandyman.com  www.hauslein.com.au

www.hauslein.com.au  up1.load90.com

up1.load90.com  wideinfo.org ```html

wideinfo.org ```html  exobacvcf.blob.core.windows.net

exobacvcf.blob.core.windows.net  www.vivo.com

www.vivo.com  shedhomesplans.blogspot.com

shedhomesplans.blogspot.com  logshedplans.blogspot.com

logshedplans.blogspot.com  logshedplans.blogspot.com

logshedplans.blogspot.com  storageshedkits.com ```html

storageshedkits.com ```html  storagearts.com

storagearts.com  woodandstorage.blogspot.com

woodandstorage.blogspot.com  www.mecalux.com

www.mecalux.com  www.pinterest.de

www.pinterest.de  www.kostorage.com

www.kostorage.com  www.amazon.com

www.amazon.com  thedailygardener.org

thedailygardener.org  www.gardennewsmagazine.co.uk

www.gardennewsmagazine.co.uk  www.artofit.org

www.artofit.org  www.storageunitsdublin.com

www.storageunitsdublin.com  storage-anywhere.com

storage-anywhere.com  kevinljackson.blogspot.com

kevinljackson.blogspot.com