shedhomesplans.blogspot.com

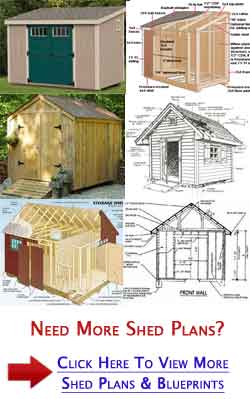

shedhomesplans.blogspot.com Introduction: Building a 12x10 Shed Building your own 12x10 shed is a rewarding project that adds valuable storage space to your property. These plans provide a detailed, step-by-step guide, ensuring a successful build. Remember to check your local building codes and obtain any necessary permits before beginning construction. This guide includes a material list to help you gather everything you need. Let's get started!

Step 1: Foundation Preparation Leveling the Ground: Start by clearing the area where the shed will be located. Remove all vegetation, rocks, and debris. Level the ground using a shovel, rake, and level. Ensure the area is perfectly flat to prevent structural issues later on. Gravel Base (Optional): For better drainage and stability, consider adding a 4-6 inch layer of compacted gravel. Compact the gravel using a plate compactor. Foundation Options: You have a few choices for the foundation: concrete slab, gravel pad with concrete blocks, or a wooden skid foundation. A concrete slab provides the most stability but requires more effort to install. Gravel and concrete blocks are a cost-effective and simpler option. A wooden skid foundation involves building a rectangular frame from pressure-treated lumber. These plans assume a gravel and concrete block foundation. Positioning Concrete Blocks: Place concrete blocks every 4 feet along the perimeter and at the center of the shed area. Ensure they are level with each other using a level and shims if necessary. These blocks will support the floor frame.

Step 2: Building the Floor Frame Cut Lumber: Using the material list, cut the lumber to the specified lengths for the floor frame. Typically, you'll need pressure-treated 2x6 lumber for the perimeter and interior joists. Assemble the Frame: Assemble the rectangular perimeter frame using screws or nails. Ensure the corners are square. Use a framing square to verify. Install Interior Joists: Install the interior joists at 16-inch centers between the perimeter frame. This will provide adequate support for the floor sheathing. Use screws or nails to secure the joists to the perimeter frame. Attach Floor Sheathing: Cut and attach 3/4-inch plywood or OSB sheathing to the floor frame using screws. Leave a small gap (1/8 inch) between the sheets to allow for expansion.

Step 3: Framing the Walls Cut Wall Studs and Plates: Cut the wall studs (usually 2x4 lumber) to the correct length. Also, cut the top and bottom plates (also 2x4 lumber) for each wall. The standard stud height is usually around 8 feet. Assemble Wall Frames: Assemble each wall frame by nailing or screwing the studs between the top and bottom plates. Space the studs 16 inches on center. Ensure the studs are straight and aligned with the plates. Frame Door and Window Openings: Include headers above door and window openings. Use appropriate sized lumber according to the plans. Attach jack studs to support the headers. Raise and Secure Walls: Raise each wall frame and position it on the floor frame. Use temporary braces to hold the walls plumb. Secure the walls to the floor frame using screws or nails. Ensure the walls are square and plumb before permanently fastening them. Connect Walls: Connect the walls together at the corners using screws or nails. Overlap the top plates for added strength.

Step 4: Installing the Roof Cut Rafters: Cut the rafters according to the roof pitch specified in the plans. The plans should provide the angle and length for the rafters. Assemble Rafters: Assemble the rafters, creating a triangular frame. Use gusset plates or plywood to strengthen the connections. Install Rafters: Position the rafters on top of the walls at regular intervals (usually 24 inches on center). Secure the rafters to the top plates using screws or nails. Install Ridge Board: Install a ridge board along the peak of the roof. This provides additional support for the rafters. Install Roof Sheathing: Cut and attach plywood or OSB sheathing to the rafters using screws. Leave a small gap between the sheets for expansion. Install Roofing Material: Install roofing felt or underlayment over the roof sheathing. Then, install the roofing material of your choice (shingles, metal roofing, etc.) according to the manufacturer's instructions.

Step 5: Installing Siding and Trim Install Siding: Install siding to the walls, starting from the bottom and working your way up. Overlap the siding according to the manufacturer's instructions. Use screws or nails designed for siding. Install Trim: Install trim around doors, windows, and corners to cover the edges of the siding and provide a finished look. Caulk and Seal: Caulk and seal all seams and joints to prevent water infiltration.

Step 6: Installing Doors and Windows Install Door Frame: Install the door frame into the framed opening. Ensure it is plumb and square. Install Door: Hang the door in the frame. Adjust the hinges as needed to ensure the door swings smoothly and closes properly. Install Window Frame: Install the window frame into the framed opening. Ensure it is plumb and square. Install Window: Install the window into the frame. Secure the window in place. Seal and Insulate: Seal around the door and window frames with caulk to prevent drafts and water leaks. Add insulation to the wall cavities if desired.

Step 7: Finishing Touches Install Interior Flooring (Optional): Install flooring inside the shed, such as plywood, vinyl, or tile. Add Shelving: Build and install shelving units to maximize storage space. Paint or Stain: Paint or stain the exterior of the shed to protect it from the elements and improve its appearance. Clean Up: Clean up all debris and materials around the shed.

Conclusion: Enjoy Your New Shed Congratulations! You have successfully built a 12x10 shed. Enjoy the added storage space and the satisfaction of completing this project yourself. With proper maintenance, your shed will provide years of reliable service.

10x12 Shed Plans With Material List Blueprint

shedhomesplans.blogspot.com

shedhomesplans.blogspot.com 12x10 Shed Plans And Material List

logshedplans.blogspot.com

logshedplans.blogspot.com 12x10 Shed Plans And Material List

logshedplans.blogspot.com

logshedplans.blogspot.com

0 komentar:

Posting Komentar